English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

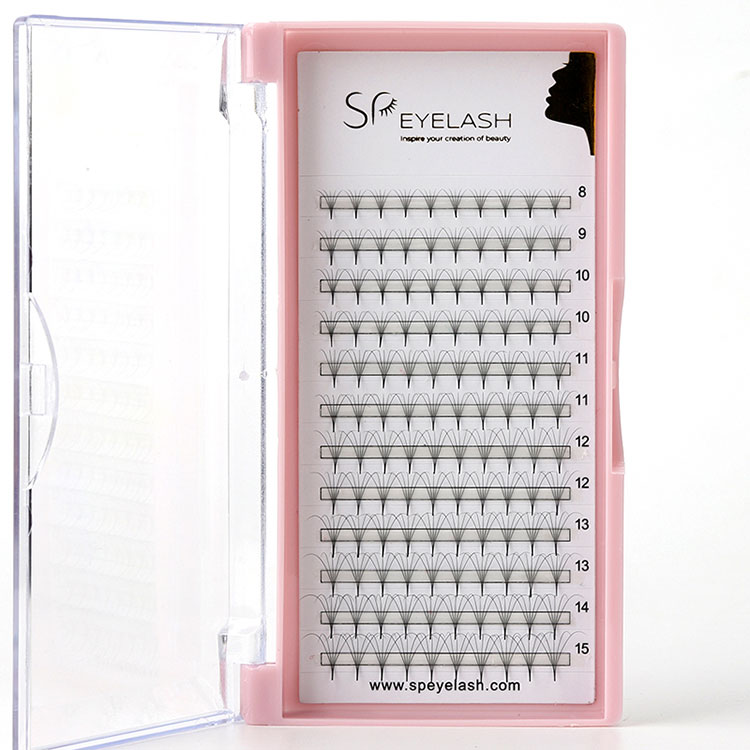

Why are premade fan lashes emerging as a standout in the global lash industry?

2025-12-18

By 2025, the global eyelash extension market is undergoing a major transformation, primarily driven by the growing popularity of pre-made fan lashes—offering convenience, efficiency, and consistent quality. Once considered a controversial alternative to hand-made lashes, pre-made lashes have evolved into a professional, salon-grade solution trusted by lash artists across Europe, North America, Australia, and other high-standard markets. Thanks to continuous advancements in manufacturing techniques, fiber quality, and heat-bonding technology, pre-made fans have become one of the fastest-growing segments in the beauty industry.

This SEO news report explores the major reasons behind the rise of premade fan lashes, what makes them different from older versions, and why lash artists, salon owners, and distributors are now embracing them as a core product line.

1. A Transformative Upgrade in Lash Technology

Premade fans were first introduced as a beginner-friendly solution, but early versions often had thick bases, visible glue, or inconsistent fan width. Many experienced lash artists resisted them, worried they might damage natural lashes or create bulky results. However, the technology has changed dramatically in recent years.

Today’s Premade Fan Lashes feature:

Ultra-thin heat-bonded bases

Symmetrical, stable fan shapes

Lightweight Korean PBT fibers

Zero stacked glue residue

Narrow, medium, and wide fan options

Perfect curl retention even in humid climates

These advancements mean artists can achieve the same fluffy volume results as handmade fans—without the intensive time and skill required to create every fan manually. Technologies like microfiber PBT, heat-sealed bonding, and laser-cut fiber tips have elevated premade fan lashes into a premium, salon-grade product.

2. Efficiency Becomes Essential for Lash Salons in 2025

One of the most important driving forces behind the rise of premade fans is efficiency. Lash salons across Europe and North America are experiencing increased customer flow, higher labor costs, and pressure for faster appointment turnover.

Compared with handmade volume fans, premades can reduce service time by 30% to 60%, allowing salons to take more clients per day. A full volume set that used to take two hours can now be completed in 60–90 minutes. For lash artists who charge by the hour or operate high-volume beauty studios, this results in higher revenue, better scheduling, and less fatigue.

In markets like Australia, where lash artists often work independently, premade fans also help prevent burnout by significantly reducing the physical strain of creating fans for several hours a day. Time-saving products have become essential, and Premade Fan Lashes are leading that evolution.

3. High Demand from Distributors and Private-Label Brands

As the salon market expands, beauty suppliers and distributors are aggressively searching for premium premade fan manufacturers. Europe, the United States, and Australia now require products that meet strict quality standards, including double-heated curls, hypoallergenic fibers, and lightweight bases.

Private-label lash brands are also booming. Many companies are requesting:

Custom trays

Unique curl options

Extreme lengths and diameters

Special strip density

Eco-friendly packaging

Manufacturers that can provide stable quality, fast lead time, and competitive wholesale prices are becoming the top choices for global lash distributors.

4. Customer Preference Shift: Comfort and Retention

Modern lash clients are more informed than ever. They understand lash mapping, fan diameter, lash weight, and retention science. More customers now request volume sets that feel light and natural—not heavy, stiff, or plastic.

Premade fans help address these expectations through:

Micro-thin bases for improved adherence

Reduced weight for everyday comfort

Heat-bonded construction that holds curl longer

Soft, realistic fiber texture

Retention has also improved for premade fans because their bases attach smoothly to natural lashes, ensuring stronger bonding and fewer early falls.

5. The Future of Premade Fan Lashes in 2025 and Beyond

The premade fan segment is expected to continue growing as technology advances. New trends already emerging include:

Nano-fiber premade fans

Seamless “invisible base” fans

Extra-dark black PBT for deeper definition

Ultra-narrow spikes for wet-lash sets

Eco-friendly biodegradable lash trays

Premium salons, educators, and influencers are now positioning premade fans as the new industry standard. As the global lash extension industry becomes more competitive, lash artists are choosing products that combine quality with efficiency—and premades deliver exactly that.

Conclusion

The rise of Premade Fan Lashes represents the beauty industry’s transition toward smarter, faster, and more consistent lash solutions. With technology, manufacturing, and market demand all pushing in the same direction, premade fans are no longer a shortcut—they are a professional tool reshaping how lash extensions are applied worldwide.